Call or Text us at

At Beach Auto Repair, our skilled technicians specialize in diagnosing and resolving

problems with your vehicle's suspension, wheel bearings, and ball joints. Whether

it's uneven tire wear, steering issues, or a bumpy ride, we swiftly identify the

problem and provide the necessary services.

Uneven tire wear, steering problems, or a rough ride can result from suspension

issues, worn wheel bearings, or damaged ball joints. Our technicians efficiently

address these issues, ensuring your vehicle offers a smooth and safe driving

experience. Contact us for top-tier suspension, wheel bearings, and ball joints

services, enhancing your vehicle's performance and safety.

Call or Text us at

There are several key aspects to be aware of when it comes to understanding the purpose of Suspension, Wheel Bearings, and Ball Joints in your vehicle. Here are some important points to consider:

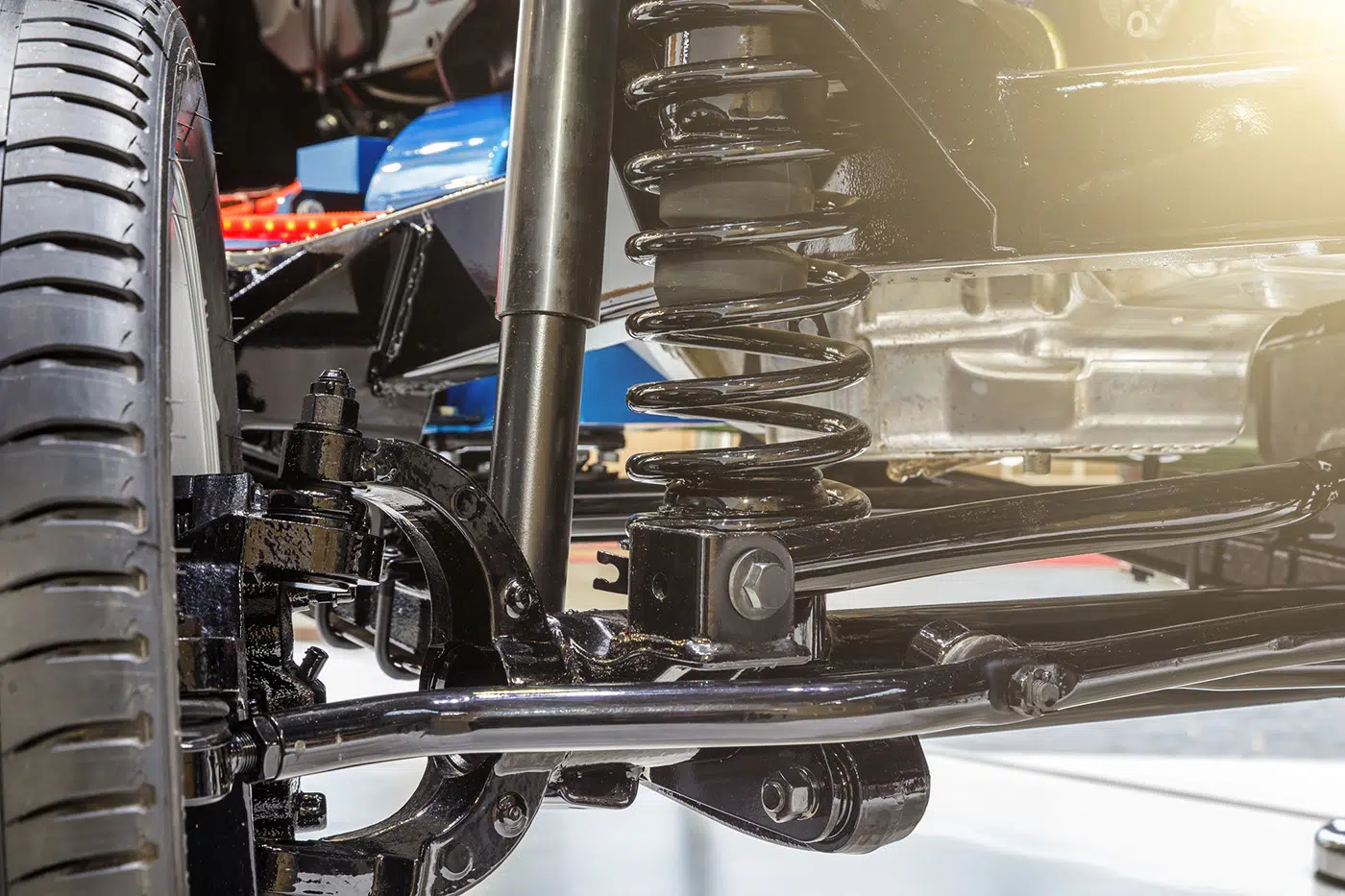

Suspension:

1. Ride Comfort: The suspension system is responsible for providing a smooth and comfortable ride by absorbing shocks and vibrations from the road surface. It ensures that passengers experience minimal discomfort and jolting, even on rough roads.

2. Handling and Stability: The suspension system plays a crucial role in maintaining vehicle stability during cornering and maneuvering. It helps distribute weight evenly among all four wheels, which enhances traction and reduces the risk of rollovers.

3. Tire Contact: Proper suspension maintains consistent tire contact with the road, which is essential for safe braking and steering. It prevents the tires from bouncing or losing grip.

4. Impact Absorption: Suspension components like struts and shock absorbers absorb impacts and prevent excessive vehicle bounce. This is vital for driver control and passenger comfort.

5. Alignment Maintenance: The suspension system helps maintain proper wheel alignment, ensuring that the vehicle tracks straight and evenly wears the tires. Misaligned wheels can lead to uneven tire wear and handling issues.

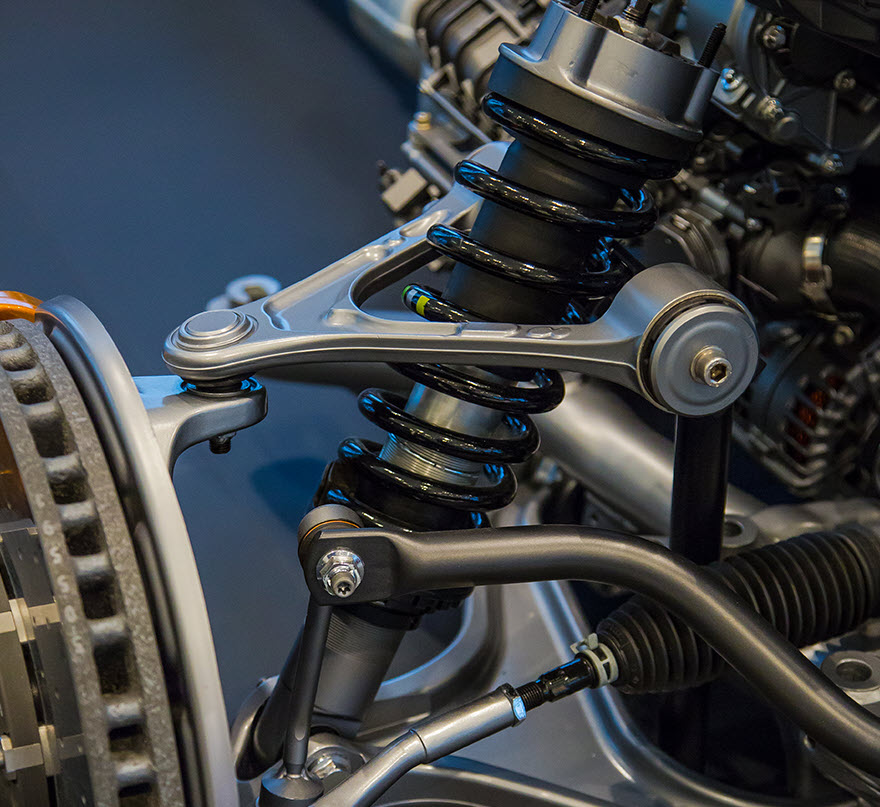

Wheel Bearings:

1. Reduced Friction: Wheel bearings reduce friction between the wheel hub and the axle, allowing the wheel to rotate smoothly. This minimizes wear and heat generation, extending the lifespan of the wheel and tire.

2. Load Distribution: Wheel bearings distribute the weight and load of the vehicle evenly across the axle. This ensures that the wheel and tire can support the vehicle's weight without excessive strain.

3. Noise Reduction: Properly functioning wheel bearings reduce noise and vibration, providing a quieter and more comfortable driving experience.

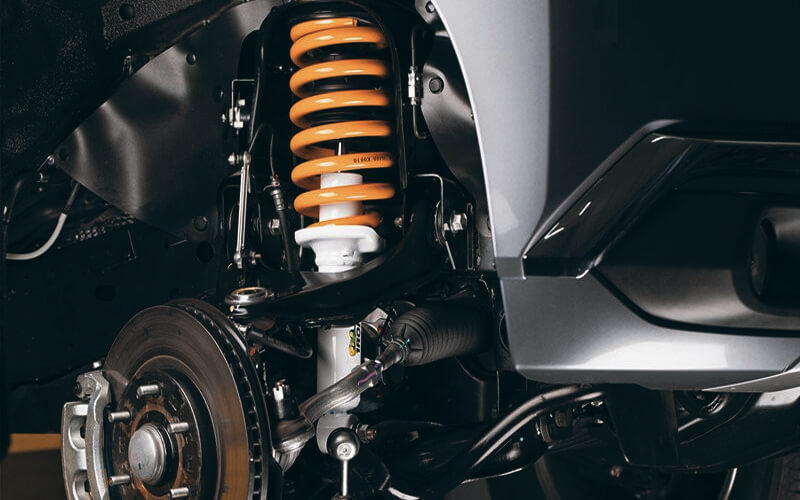

Ball Joints:

1. Steering Control: Ball joints are integral to the vehicle's steering system. They allow the front wheels to pivot when steering, ensuring precise control and responsiveness.

2. Suspension Movement: Ball joints permit controlled up-and-down movement of the suspension while maintaining a connection to the steering system. This allows the suspension to flex over bumps without affecting steering stability.

3. Safety: Ball joints are critical for safe handling and steering response. A worn or damaged ball joint can lead to steering issues, poor handling, and potentially, loss of control.

4. Alignment Integrity: Like suspension components, ball joints also play a role in maintaining proper wheel alignment. They help keep the front wheels aligned, ensuring even tire wear and predictable steering.

By understanding the purpose of Suspension, Wheel Bearings, and Ball Joints in your vehicle, you can appreciate their vital roles in providing a comfortable and safe driving experience, as well as maintaining proper steering and handling characteristics.

There are several key aspects to be aware of when it comes to understanding common failures of Suspension, Wheel Bearings, and Ball Joints in your vehicle. Here are some important points to consider:

Suspension:

1. Worn Shock Absorbers: Over time, shock absorbers can lose their effectiveness, leading to reduced ride comfort, increased bounce, and poor handling. Worn shocks should be replaced to restore optimal suspension performance.

2. Broken Springs: Coil or leaf springs can break due to excessive stress or corrosion. A broken spring can cause an uneven ride height, poor handling, and loss of stability. Replacing broken springs is essential for safety.

3. Leaking Struts or Shocks: Leaking fluid from struts or shocks indicates internal damage. This can result in reduced damping, leading to an uncomfortable and less controllable ride. Leaking struts or shocks should be replaced.

4. Sagging or Unbalanced Suspension: Sagging or uneven suspension can lead to uneven tire wear and reduced handling. Proper diagnosis and correction of sagging or imbalanced suspension components are crucial.

5. Noisy Bushings: Worn or damaged suspension bushings can produce clunking or squeaking noises when driving over bumps. Replacing these bushings can eliminate the noise and improve suspension performance.

Wheel Bearings:

1. Loud Grinding Noise: A common sign of wheel bearing failure is a loud grinding or growling noise, often more pronounced when turning. This noise can indicate worn or damaged wheel bearings that need replacement.

2. Wheel Vibration: A vibrating steering wheel or vehicle at certain speeds can be a sign of a compromised wheel bearing. Vibration indicates that the bearing isn't rotating smoothly and needs attention.

3. Uneven Tire Wear: When a wheel bearing is faulty, it can cause uneven tire wear. It's important to address this issue promptly to prevent further damage and extend tire life.

Ball Joints:

1. Loose Steering: If ball joints wear out, you may experience loose or imprecise steering. This can affect your ability to control the vehicle and should be addressed immediately.

2. Knocking or Clunking Sounds: Worn ball joints can produce knocking or clunking noises, especially when going over bumps or making turns. These sounds are indicative of ball joint problems.

3. Uneven Tire Wear: Faulty ball joints can result in uneven tire wear, causing tires to wear out prematurely and requiring more frequent replacements.

4. Steering Pull: A vehicle with worn ball joints may pull to one side during driving. This not only affects handling but can also be a safety concern.

By understanding these key points about common failures of Suspension, Wheel Bearings, and Ball Joints in your vehicle, you can recognize the signs of trouble and take appropriate action to maintain safe and comfortable driving conditions.

There are several key aspects to be aware of when it comes to servicing Suspension, Wheel Bearings, and Ball Joints in your vehicle. Here are some important points to consider:

Suspension:

1. Regular Inspection: Routine inspection of the suspension system is essential to detect early signs of wear, damage, or alignment issues. Inspections should cover components like struts, shocks, springs, control arms, and bushings.

2. Alignment Check: Proper wheel alignment ensures even tire wear and predictable handling. Regularly check and adjust the wheel alignment as needed, especially after hitting potholes or curbs.

3. Shock and Strut Replacement: Worn or damaged shock absorbers and struts should be replaced to maintain ride comfort, handling, and safety. A professional technician can assess the condition and recommend replacements.

4. Spring Maintenance: Coil or leaf springs should be inspected for signs of sagging, cracking, or breakage. Worn springs should be replaced to restore ride height and handling.

5. Bushings and Mounts: Suspension bushings and mounts play a crucial role in reducing noise and vibration. If they're worn or damaged, they should be replaced to improve ride quality.

Wheel Bearings:

1. Diagnostic Testing: When you suspect wheel bearing issues, professional diagnostic tests can determine the extent of the problem. These tests may include measuring play or noise levels and vibration analysis.

2. Wheel Bearing Replacement: If a wheel bearing is found to be faulty, it should be replaced promptly. This is a precision job and should be performed by a qualified mechanic to ensure proper installation.

3. Proper Lubrication: Greasing wheel bearings during servicing is essential to extend their lifespan. Timely and proper lubrication reduces friction and heat buildup.

Ball Joints:

1. Regular Inspection: Routine inspection of ball joints helps detect any signs of wear, play, or damage. This should be part of your vehicle's regular maintenance schedule.

2. Replacement as Needed: If a ball joint shows signs of wear, excessive play, or damage, it should be replaced promptly. Ball joint replacement should be performed by a qualified technician to ensure safety and proper alignment.

3. Wheel Alignment: After ball joint replacement, it's important to check and adjust the wheel alignment. Proper alignment ensures that the vehicle handles well and tires wear evenly.

4. Greasing and Lubrication: Some ball joints have fittings for greasing. Regular greasing can extend the life of the ball joint and ensure smooth movement.

By understanding these key points about servicing Suspension, Wheel Bearings, and Ball Joints in your vehicle, you can ensure that these critical components are well-maintained, contributing to a safe, comfortable, and reliable driving experience.

Let us know how we can help.