Call or Text us at

At Beach Auto Repair, our skilled technicians specialize in addressing issues

related to car starters. Whether it's a clicking sound when you turn the key,

grinding noises, or a completely unresponsive starter, our team swiftly diagnoses

the problem and proceeds with the necessary repairs.

Clicking sounds, grinding noises, or a non-functional starter can be attributed to a

faulty solenoid or a worn-out starter motor. Our experts excel at efficiently and

effectively resolving these problems, ensuring your vehicle starts reliably and

smoothly. Don't hesitate to reach out to us for high-quality car starter services

that guarantee a hassle-free and dependable driving experience.

Call or Text us at

Understanding the purpose of a vehicle's starter is essential for comprehending its role in the engine's ignition process. Here are some key points to consider:

1. Engine Cranking: The primary purpose of a vehicle's starter is to initiate the engine's cranking process. When you turn the ignition key or press the start button, the starter motor engages with the engine's flywheel or flexplate, enabling the engine to turn over.

2. Ignition Sequence: The starter's function is crucial in the ignition sequence. It rotates the engine's internal components, allowing the spark plugs to create sparks that ignite the air-fuel mixture, initiating the combustion process.

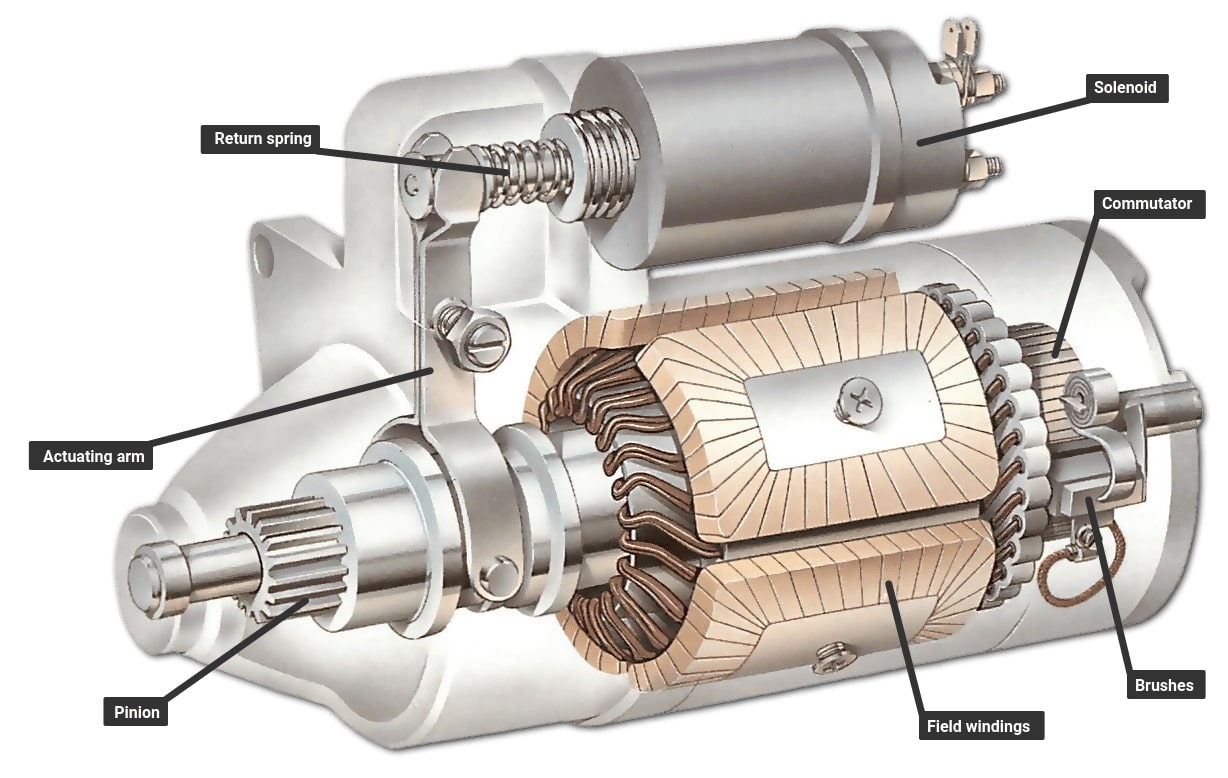

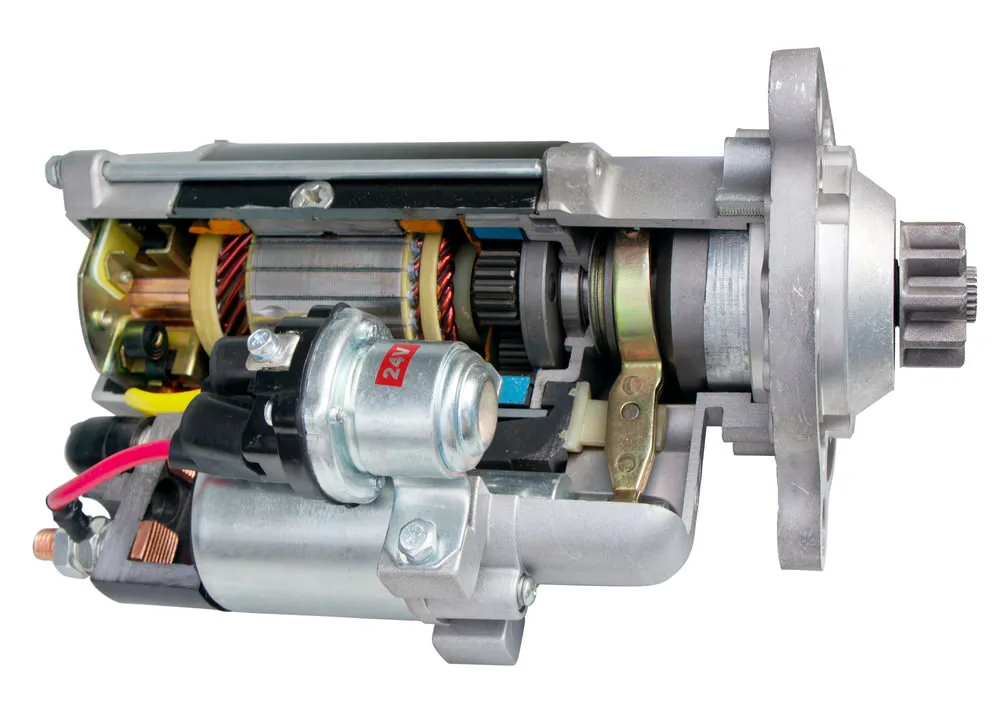

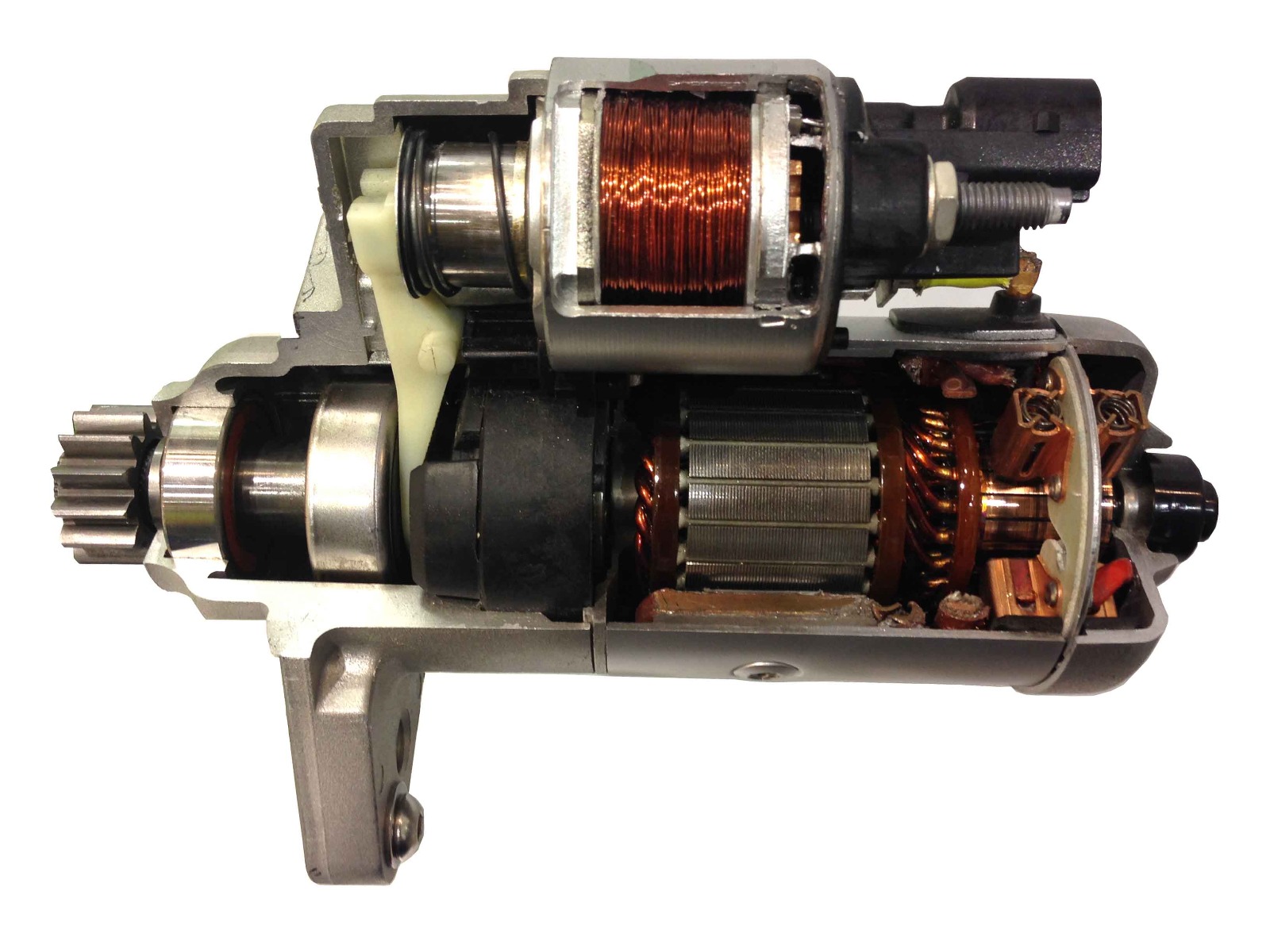

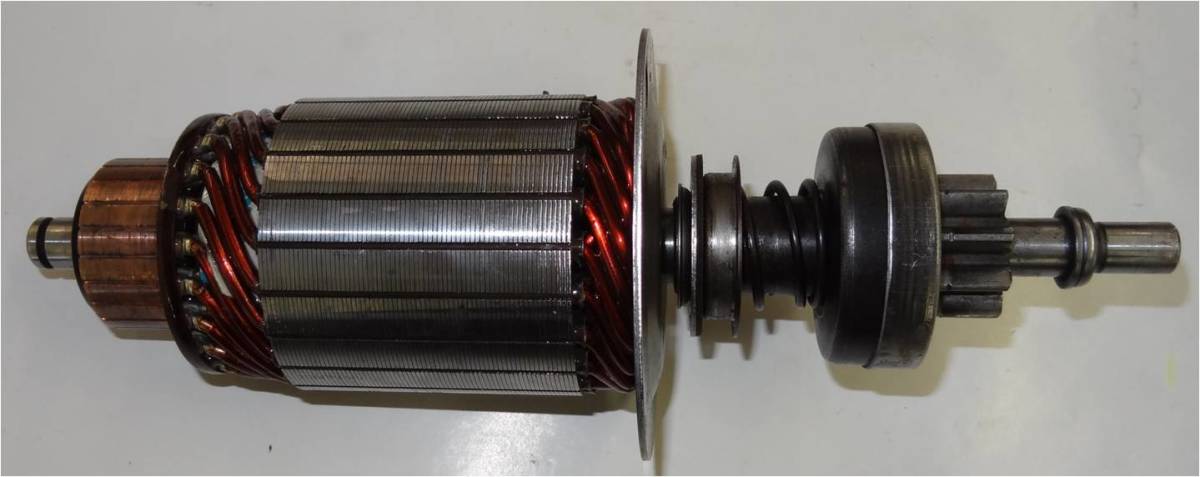

3. Mechanical Engagement: The starter motor is equipped with a small gear called a pinion gear. This gear meshes with the engine's flywheel teeth or flexplate ring gear, creating a mechanical connection that transfers the starter motor's rotational force to the engine.

4. Initial Crank: The starter provides the initial force to overcome the engine's static state and set it in motion. This is especially important when the engine is cold or hasn't run for a while, as it requires more energy to overcome internal friction.

5. Assisting Compression Stroke: The starter's rotational force helps the engine complete its compression stroke. This stroke builds pressure within the cylinders, preparing them for combustion.

6. Supporting Fuel Injection: In modern fuel-injected engines, the starter helps in creating the necessary vacuum to initiate the fuel injection process, enabling the engine to start smoothly.

7. Electric Systems Activation: While the starter is engaged, various electric systems are temporarily disabled to divert maximum power to the starter motor. This prevents power drain and ensures that all available energy is used for starting the engine.

8. Crankshaft Movement: The starter's action rotates the crankshaft, which in turn drives other engine components, such as the camshaft and auxiliary systems.

9. Reliable Cold Starts: The starter's function is crucial during cold weather when engines are harder to turn over due to increased viscosity of fluids and other cold-related factors.

10. Hybrid and Electric Vehicles: In hybrid and electric vehicles, the starter's role might be different, as these vehicles often rely on electric motors for both propulsion and initiating the engine.

11. Ignition Timing: The starter's action affects the engine's initial timing. Correct ignition timing is crucial for efficient combustion and overall engine performance.

12. Backup Starting: In the event of a battery failure, a functioning starter allows jump-starting the vehicle using another power source, like another vehicle's battery.

13. Emission Control: The starter's role in initiating combustion contributes to proper emission control by ensuring efficient combustion in the engine's cylinders.

14. Overall Engine Functionality: The starter's purpose is intertwined with the engine's ignition and operation, ensuring the engine starts reliably and contributes to smooth operation.

By understanding the multifaceted purpose of a vehicle's starter, you gain insight into its significance in the engine's ignition process and overall functionality.

Understanding common failures of automotive starters is essential for diagnosing and addressing starting issues. Here are some key points to consider:

1. Solenoid Failure: The starter solenoid is responsible for engaging the starter motor. A failed solenoid can prevent the starter from engaging, resulting in a "clicking" sound when you try to start the engine.

2. Worn Starter Motor Brushes: Starter motors use brushes to maintain electrical contact. Over time, these brushes can wear down, leading to intermittent or no contact, causing the starter to fail to engage.

3. Corroded or Loose Connections: Corrosion or loose connections at the starter terminals can hinder electrical flow, preventing the starter from receiving the necessary power to engage.

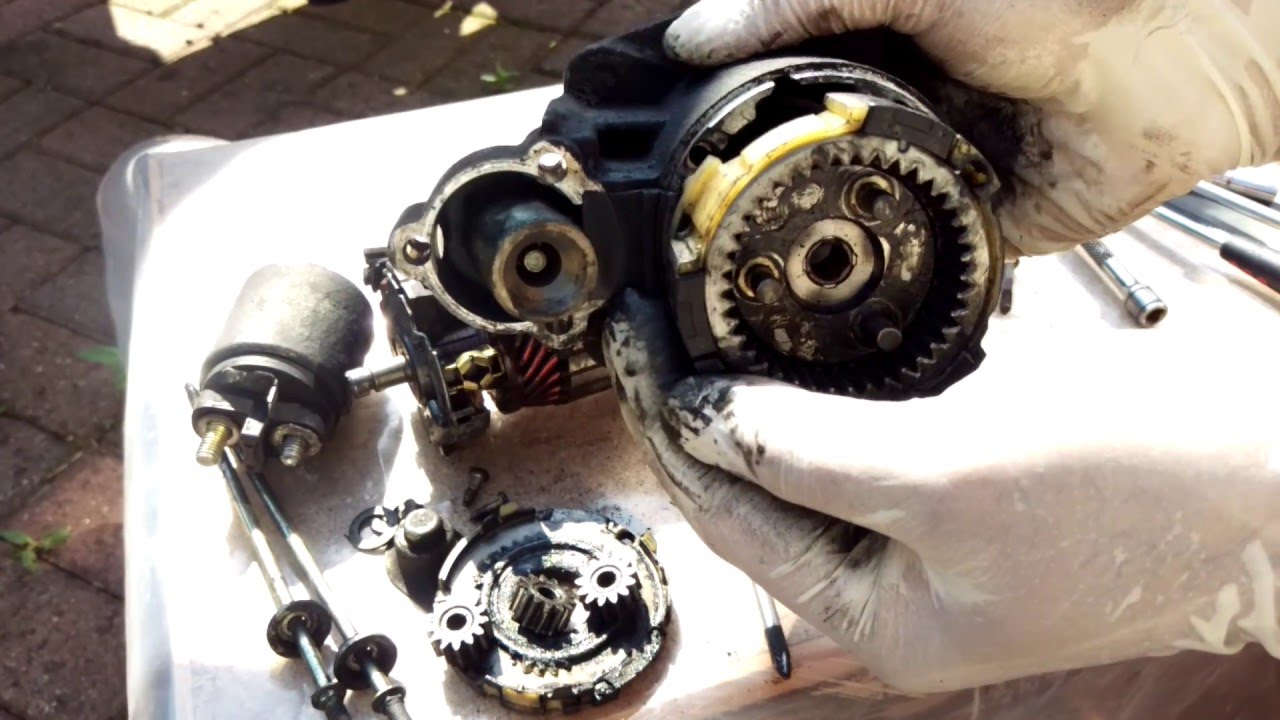

4. Bendix Drive Issues: The Bendix drive is a gear mechanism that engages the starter motor with the flywheel or flexplate. If the Bendix drive becomes worn or damaged, it can cause a grinding noise or prevent the starter from engaging properly.

5. Faulty Ignition Switch: A malfunctioning ignition switch can prevent the starter circuit from receiving the signal to engage. This can lead to a no-start condition.

6. Frozen or Stuck Components: In cold climates, starter components, including the Bendix drive, can become frozen or stuck due to moisture or freezing temperatures. This can prevent the starter from engaging.

7. Mechanical Binding: Mechanical issues within the starter, such as binding of internal components, can hinder the starter's operation.

8. Excessive Wear on Flywheel or Flexplate Teeth: If the teeth on the flywheel or flexplate become worn or damaged, the starter's gear may not engage properly, leading to a clicking sound or failure to start.

9. Low Battery Voltage: A weak or drained battery can result in insufficient voltage reaching the starter motor, causing slow or no cranking.

10. Faulty Starter Relay: The starter relay controls the flow of electrical current to the starter motor. A malfunctioning relay can prevent the starter from engaging.

11. Overheating: Excessive heat due to proximity to exhaust components or prolonged cranking attempts can damage the starter's internal components.

12. Age and Wear: Like any mechanical component, starters have a limited lifespan. Over time, internal parts can wear out, leading to diminished performance or complete failure.

13. Voltage Drop: High resistance in the starter circuit due to corroded cables or connections can lead to voltage drop, resulting in insufficient power reaching the starter motor.

14. Seized Starter Motor: A seized starter motor, often caused by lack of lubrication or internal damage, prevents the motor from turning and engaging with the engine.

By understanding these common starter failure points, you can troubleshoot starting issues more effectively, take preventive measures, and ensure your vehicle reliably starts when needed.

.jpg)

.jpg)

Properly servicing an automotive starter is crucial for maintaining reliable engine ignition. Here are some key points to consider:

1. Regular Inspection: Incorporate the starter into your routine vehicle maintenance. Periodically inspect the starter and its components for signs of wear, damage, or corrosion.

2. Listening for Unusual Noises: Pay attention to any abnormal noises, such as grinding, whirring, or clicking, when you turn the ignition key. These sounds could indicate issues with the starter motor or its components.

3. Checking Electrical Connections: Ensure that the electrical connections to the starter are secure and free from corrosion. Poor connections can lead to voltage drop and affect the starter's performance.

4. Testing Voltage: If the starter doesn't engage or turns slowly, use a multimeter to measure the voltage at the starter terminals. Low voltage could indicate a problem with the battery, cables, or connections.

5. Testing Starter Solenoid: The starter solenoid plays a crucial role in engaging the starter motor. Test its operation using a multimeter or a remote starter switch.

6. Cleaning and Lubrication: Over time, dirt and debris can accumulate around the starter. Clean the area around the starter to prevent contaminants from affecting its operation. Lubricate movable parts according to manufacturer recommendations.

7. Starter Brushes Inspection: If your starter has replaceable brushes, inspect them for wear. Worn brushes can lead to intermittent contact and reduced starter performance.

8. Checking the Flywheel or Flexplate: If the starter engages but doesn't crank the engine, the flywheel or flexplate teeth might be worn. Inspect these components for damage and ensure proper alignment.

9. Diagnosing Voltage Drop: Perform a voltage drop test to identify any resistance in the starter circuit. Excessive voltage drop can indicate issues with cables, connections, or other components.

10. Rebuilding or Replacement: If you have the skills, you might consider rebuilding the starter by replacing worn components. However, in many cases, a professional replacement is more cost-effective and time-efficient.

11. Professional Diagnosis: If you're not experienced in automotive electrical systems, consult a professional mechanic for accurate diagnosis and repair. They have the tools and expertise to identify specific starter issues.

12. Addressing Heat Issues: Excessive heat can degrade the starter's performance. Ensure that the engine's heat shields are intact and that the starter is not positioned too close to heat sources.

13. Battery Health: A weak or failing battery can strain the starter. Ensure your vehicle's battery is in good condition to prevent undue stress on the starter motor.

14. Protective Gear: When working on the starter, wear appropriate safety gear, including gloves and eye protection, to prevent injury.

By understanding these key points and staying proactive in servicing your automotive starter, you can ensure reliable engine ignition, prevent unexpected starting issues, and maintain your vehicle's overall functionality.

Let us know how we can help.